| We are one of the leading manufacturers and suppliers of an extensive range of flanges, we offer blind flanges that are high on utility. These blind flanges are used to close the ends of valves, pressure vessel openings, pipes and other channels where one end needs to be blocked. Made with top quality raw material, these blind flanges are high on durability and performance. Our blind flanges can be customized on various parameters, that the client might feel suitable. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A Blind Flange is which has no bore, and is used to close ends of piping systems. A blind flange also permits easy access to a line ones it has been sealed. The blind flange is sometimes machined to accept a pipe of the nominal Size to which reduction is being made. The reduction can be either threaded or welded. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Our organization offers a wide range of Blind Flanges, which is widely used to close ends of piping systems. These flanges are round plate with no center hold but with all the proper bolt holes. We offer our range in various sizes and material, which is used to provide positive closer on the ends of pipes, valves, or equipment nozzles. The Blind flanges also help in easy access to a line once it has been sealed. These are available in custom made finishes or in standard sized pipe to which reduction is being made. Further, this reduction can be a threaded reduction or welded reduction. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Blind flanges are designed for tolerating highest pressure and working in several conditions. Our company is known as a leading trading industry in manufacturing and supplying an exclusive range of blind flanges. These flanges are used for closing the end of the pipe, valve, pressure vessel etc. these flanges are frequently used in paper and pulp industries. We are known manufacturer and exporter of blind flanges and our product is highly acclaimed in international market for its premium quality and durability. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blind Flanges | Blind Flanges Manufactures | Blind Flanges Exporters | Blind Flanges SuppliersBlind Flange | Blind Flange Manufacturers | Blind Flange Exporters | Blind Flange SuppliersBlind Flanges Manufacturers India | Blind Flanges Exporters India | Blind Flanges Suppliers India |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MATERIAL USED

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FEATURES

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

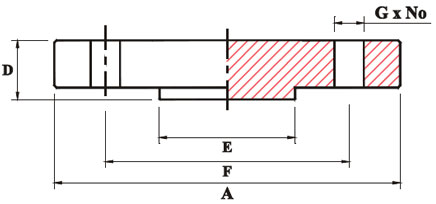

Notes :- Flange dimensions to ANSI to B16.5.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||