|

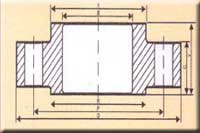

A Slip-On Flange is bored sightly larger than the outer Diameter of the matching pipe. The pipe slip into the flange prior to welding both inside and outside to prevent leaks.The British standard flanges manufactured by us pertain to all standards like BS10 1962 Table D,E,F,H IS 6392 Table 5,17,26 IS 1538 in slip. These are manufactured using mild steel both in slip-on and blind type. Our quality slip on flanges are ideal for lower pressure applications. Their ease of fitting and welding reduces fabrication costs. Our professional engineering team is involved in innovating durable and high-quality products to cater to our clients' needs. Detailed Product Description of Slip-On Flange :-The slip-on flange has a low hub because the pipe slips into the flange prior to welding. It is welded both inside and out to provide sufficient strength and prevent leakage. They are ideal for low pressure applications. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| We offer an extensive range of Slip on Flanges, which is a very popular type of pipe flanges. These flanges slide over the end of piping and then welded in place. Slips on Flanges are perfect for lower pressure applications and can be easily fitted & welded into different pipes. The welding helps to reduce the fabrication costs of these pipes. We offer our range in wide variety of sizes for various applications. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Slip on flanges are used for providing slips on flanges. These flanges are having large diameter than pipe, which slips on it. These flanges are flexible to use with lower pressure. Flanges manufactured by us are meeting all international standard. We are having one of the largest manufacturing unit of flanges of all types. We are using latest technology and premium quality raw material in the manufacturing of flanges. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slip-On Flanges | Slip-On Flanges Manufactures | Slip-On Flanges Exporters | Slip-On Flanges SuppliersSlip-On Flange | Slip-On Flange Manufacturers | Slip-On Flange Exporters | Slip-On Flange SuppliersSlip-On Flanges Manufacturers India | Slip-On Flanges Exporters India | Slip-On Flanges Suppliers IndiaSlip On Flanges | Slip On Flanges Manufactures | Slip On Flanges Exporters | Slip On Flanges SuppliersSlip On Flange | Slip On Flange Manufacturers | Slip On Flange Exporters | Slip On Flange SuppliersSlip On Flanges Manufacturers India | Slip On Flanges Exporters India | Slip On Flanges Suppliers India |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Material specifications: Carbon steel: ASTM a 105, a266 Low alloy steel: ASTM a 182 grade f1, f5, f6, f7, f9, f11, f12, f21, f22 Standard dimensions: Ranging: 0.5" to 24" as per ANSI b16.5, bs 4504, bs-10, asme b 16.36. 26" - 72" as per mss sp44, api -605, awwac-207-55, asme b 16.47, bs 3263 Standard facing: Raised face, ring - type, flat face, male - female, tongue - groove.welded both inside and out to provide sufficient strength and prevent leakage.They are ideal for low pressure applications. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MATERIAL USED COMMON MATERIAL USED IS AS FOLLOWS

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FEATURES

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ADVANTAGES OF SLIP ON FLANGES

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||