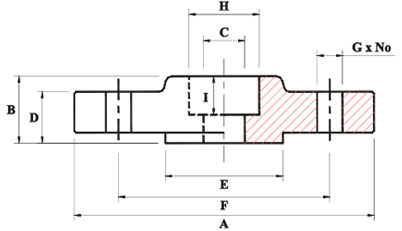

| This flange is similar to slip-on flange, except they a bore and a counter bore. The counter bore is slightly larger than the Outer Diameter of the matching pipe, allowing the pipe to be inserted. A restriction is built into the bottom of the bore, which acts as a shoulder for the pipe to rest on, and has the same ID of matching pipe. The flow is not restricted in any direction. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| We are offering a comprehensive range of Socket Weld Flanges with one of the best quality in the industry. These flanges are designed for working flawlessly in high pressure. Our product is highly appreciated in many international markets. We have used premium quality material in the construction of Socket Welding Flanges. We are having highly skilled team of workers and advance technology. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow. When provided with an internal weld, the static strength of this flange is equal to slip-on flange, but the fatigue strength is 50% greater than double welding slip-on flanges. Smooth bore conditions in such a flange can easily be attained without having to bevel the flange face and, after welding, to reface the socket weld flange as would be required with slip-on flanges. For this reason, the internally welded flange is popular in chemical process piping. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| With our expertise in the respective field, we are engaged in offering an extensive range of Socket Weld Flanges. These flanges are a device, which is welded to the end of pipe so that the pipe can be bolted to another pipe with a similar flange. Our range of socket weld flanges helps to disconnect or reconnect the pipe with ease. We offer these flanges in variety of shape and sizes, which is known for their durability and high performance. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Socket Welding Flanges | Socket Welding Flanges Manufactures | Socket Welding Flanges Exporters | Socket Welding Flanges SuppliersSocket Welding Flange | Socket Welding Flange Manufacturers | Socket Welding Flange Exporters | Socket Welding Flange SuppliersSocket Welding Flanges Manufacturers India | Socket Welding Flanges Exporters India | Socket Welding Flanges Suppliers IndiaSocket Weld Flanges | Socket Weld Flanges Manufactures | Socket Weld Flanges Exporters | Socket Weld Flanges SuppliersSocket Weld Flange | Socket Weld Flange Manufacturers | Socket Weld Flange Exporters | Socket Weld Flange SuppliersSocket Weld Flanges Manufacturers India | Socket Weld Flanges Exporters India | Socket Weld Flanges Suppliers India |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials used:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Key Features:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Uses of socket weld flanges:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes :- Flange dimensions to ANSI B16.5. Dimensions "B" & "D" includes raised face thickness. Bore (SCH) "C" purchasess to Specity. Larger outlet sizes are avilable on applications. ANSI 150# / 300# 2mm Raised Face. ANSI 600# / 2500# 7mm Raised Face.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||